IRPD supplies an Additive Machine Tool "Made in Switzerland" to Ecoparts

IRPD from St. Gallen has received an order from Ecoparts in Hinwil, Switzerland for an IMPACT 4530, a state-of-the-art additive machine tool. The collaboration represents a significant step forward for both companies in the field of industrial additive manufacturing and underlines their shared commitment to technological innovation and sustainable production "Made in Switzerland".

The collaboration with Ecoparts, a leading service provider in the field of additive manufacturing, represents a strategically important step for IRPD. "With Ecoparts as the market leader in the service sector, we have found the ideal partner. We look forward to further developing the systems together and adapting them to the requirements of the market based on Ecoparts' valuable input," explains Stefan Lang, CEO of IRPD.

Ecoparts is also very enthusiastic: Denis Forster, CEO of Ecoparts, emphasizes: "It is important for us to shape the future together with a strong local partner. The IMPACT offers us the opportunity to achieve very high productivity and manufacture parts in a wide variety of metals." This flexibility was a decisive criterion for the choice of the new system.

Daniel Kündig, co-founder and Head of Technology at Ecoparts, adds: "The IMPACT machine concept has convinced us. We can expand our range and benefit from the latest technological developments. What is particularly interesting for us is that the system can be automated relatively easily at a later date using robotics. We are therefore opting for a future-proof solution."

Another advantage is the IMPACT 4530's ability to produce larger components - a growing need in the industry, as Adrian Helbling, co-founder and Head of Marketing and Sales at Ecoparts, explains: "We have been seeing a demand for larger parts in the industry for some time. With the IMPACT, we can now produce such components in one piece and thus offer customers new possibilities."

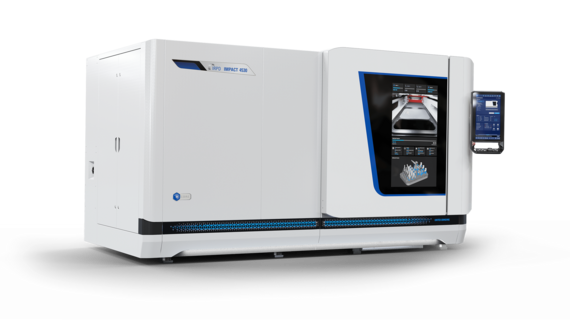

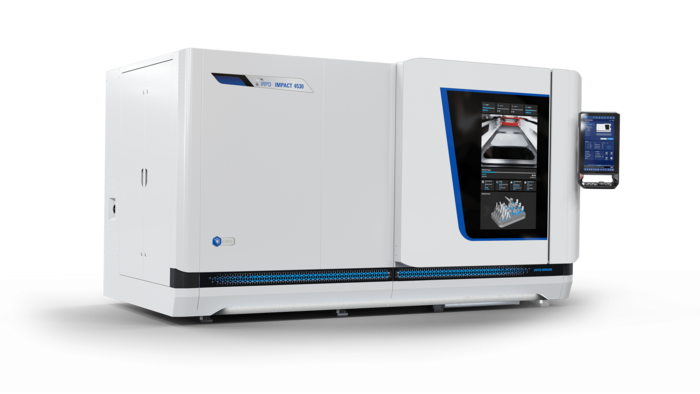

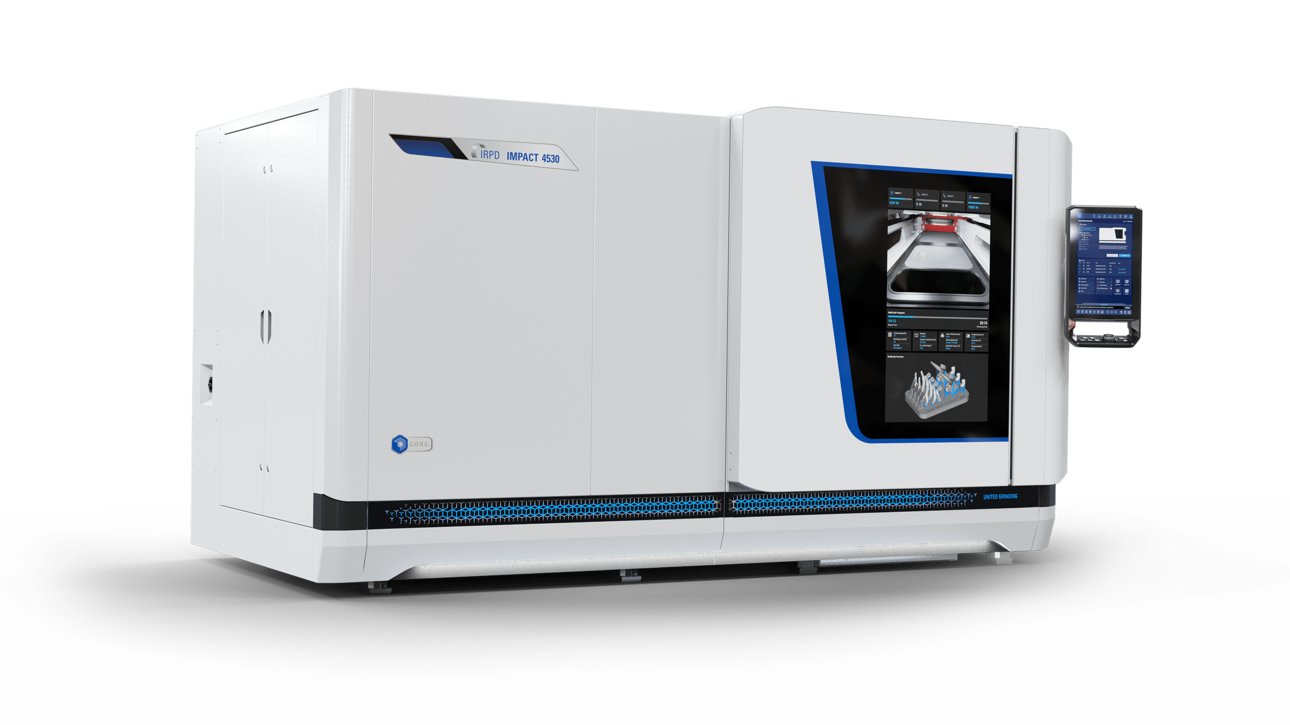

The IMPACT 4530 is an additive machine tool for metal parts developed in Switzerland that meets the high demands of industrial applications. With a generous build volume of 450 x 300 x 400 mm and two or four fiber lasers with 1,000 watts each, it enables very high build rates. The flexible build and powder container system allows fast material and job changes, while the multifunctional recoater with automatic recoater lip drum ensures smooth continuous operation. The system can also be scaled from a stand-alone machine to a fully automated system network.

The sale of the IMPACT 4530 to Ecoparts not only strengthens the innovative power of both companies but also sends a clear signal for the future viability of Switzerland as a manufacturing location.